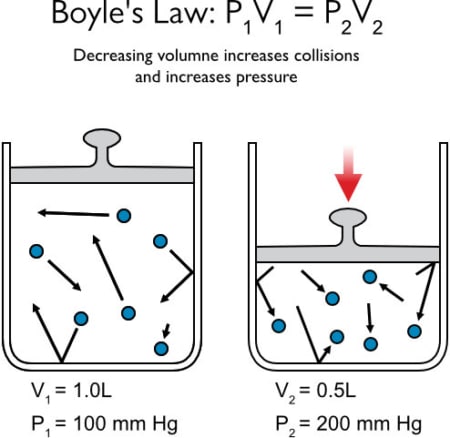

Boyle’s Law

(New) Compressed Air vs Air Blowers

test excerpt here!

How Air Knife Systems Work

Air Knives are often the most efficient and effective method of removing or controlling foreign substances for any surface.

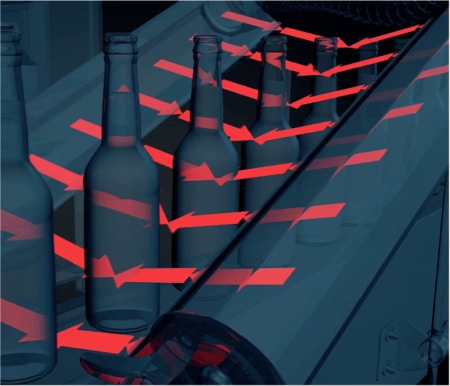

Most Air Knives are stationary with products passing through them on a conveyor however there are also systems where the product is stationery and the Air Knives move around it.

What Are Air Knives Used For

Air Knives are highly effective tools, used in manufacturing, for a wide variety of applications and purposes. They are a vital part of the production line for many industries, such as those that work in food and beverage, industrial and electronic, automotive and aerospace, and rubber and plastics.

How Air Knives Work

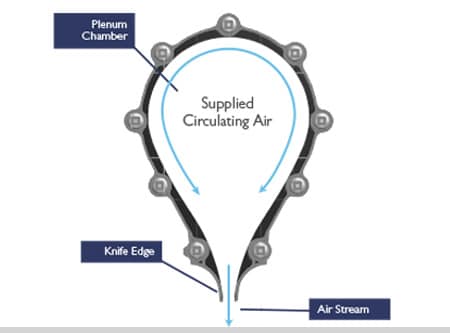

An industrial air knife is a pressurized air plenum chamber with a continuous slot through which pressurised air exits in a laminar (uniform) flow pattern. The exit air velocity creates an impact air velocity onto the surface of products that the air is directed toward.

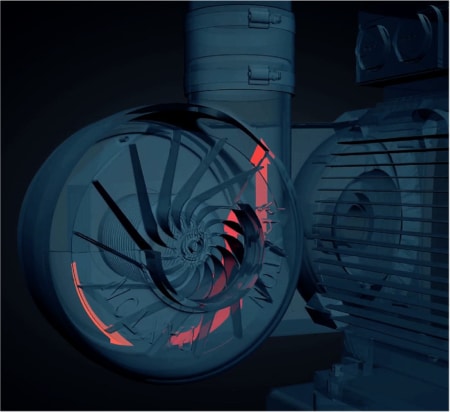

How Air Blowers Work

Air Blowers are devices designed to take in air at an inlet, and expel it at an outlet, whilst increasing both the speed and the volume of air.

Compressed Air vs Air Blowers

Air Blowers and compressed air machines are the two main devices used by manufacturers to create high-speed air streams for industrial use.

The main difference between compressors and blowers is the pressure ratio. Compressors operate at a high-pressure ratio, and blowers a low-pressure ratio.

The History Of Air Knives

Air Knife Systems came into widespread use following the historic Montreal Protocol.

They were, however, around for decades before this, drawing on pioneering work from both engineering and physics.