Top 5 FAQ's

Our systems are the main difference between. They are commonly used for applications that require a relatively lower pressure.-

What is an Air Knife?

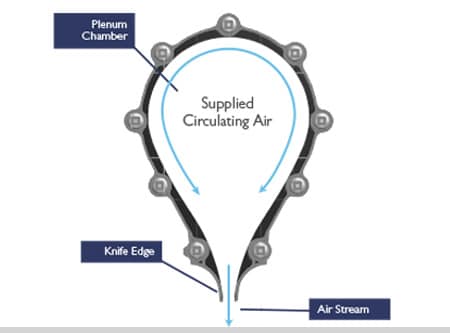

An industrial Air Knife is a tool designed to eject a high-intensity, uniform air flow that cleans, dries and/or protects a wide range of objects.

An Air Knife is a pressurized air plenum chamber, containing continuous slots, through which air is ejected in a way that creates a high-intensity, uniform and therefore laminar air flow.

Air Knives are available in a range of shapes, sizes and materials, but are usually made from aluminium or stainless steel. The design means that typically one side is shaped into a point that resembles a knife edge, and this is where Air Knives get their name from.

Read more about the History of Air Knives and how they work.

-

What is an Air Knife?

An industrial Air Knife is a tool designed to eject a high-intensity, uniform air flow that cleans, dries and/or protects a wide range of objects.

-

What is an Air Knife?

An industrial Air Knife is a tool designed to eject a high-intensity, uniform air flow that cleans, dries and/or protects a wide range of objects.

-

What is an Air Knife?

An industrial Air Knife is a tool designed to eject a high-intensity, uniform air flow that cleans, dries and/or protects a wide range of objects.

-

What is an Air Knife?

An industrial Air Knife is a tool designed to eject a high-intensity, uniform air flow that cleans, dries and/or protects a wide range of objects.

Air Knife Brochures

Our systems are the main difference between compressors and blowers is the pressure ratio. Blowers, on the contrary, are designed to provide a moderate increase in pressure compared to the atmospheric pressure. They are commonly used for applications that require a relatively lower pressure.Benefits of a SolvAir Air Knife System

Improved production line performance, low maintenance, energy and cost-saving Air Knife Systems that can be easily added onto production lines and adapted to meet your needs. All SolvAir Air Knife systems uniquely provide the following key benefits:

3 Year Warranty

100% Performance Guarantee