With electricity costs shooting upwards, it's more important than ever for industrial and manufacturing businesses to be as energy-efficient as possible. That's why switching from compressed air systems to blower-driven low-energy Air Knives can be a smart move.

High Costs of Business Energy Use

Just about every business in the UK is impacted in some way by the cost of energy. However, for high users such as industrial and manufacturing companies, business energy costs can make up a significant chunk of their overhead liabilities. Therefore, rising prices can seriously affect the profitability and financial stability of the business.

Against this backdrop, it's no wonder that many industrial and manufacturing businesses are reviewing their production lines systems, in many cases with a particular focus on compressed air energy efficiency. Compressed air systems may be relatively cheap and easy to install, but their high operating costs are often overlooked when production lines are planned and deployed.

Fortunately, there's a more energy-efficient alternative that's also cost effective. Installing a blower-powered Air Knife system can deliver big energy savings compared to alternative solutions which use compressed air, heating and manual intervention. Using high-velocity, laminar airflows generated by an energy-efficient, high-performance centrifugal blower, precision-engineered Air Knives can create air jets suitable for a wide range of industrial and manufacturing applications.

Why is air compressor energy efficiency an issue?

In simple terms, compressed air wastes energy. In many cases, as little as 10% of the electricity used to power a compressed air system is converted into usable energy.

What's more, many systems can waste compressed air through leaks, poor maintenance or inefficient workflows.

When you take into account that systems can eat up as much as 30% of a site's electricity usage, it's clearly a real challenge to achieve significant compressed air energy savings.

What's the alternative?

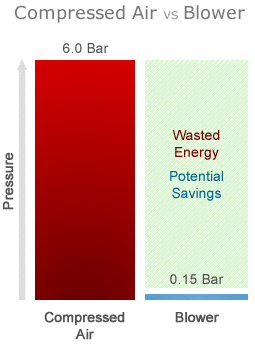

Low-energy Air Knives powered by energy-efficient blowers can deliver major energy savings. Compressed air systems use over 12 times as much energy versus a comparable air blower system.

In a compressed air system, the air being released to atmospheric pressure has undergone the compression process from 0 to 6 Bar. However, the majority of applications only need a system pressure of 0.15 bar, so a huge amount of energy is wasted. Air Knife Systems achieve the pressure required to deliver the air from generation to discharge at a much lower rate than 6 bar, typically up to 0.25 Bar. So, they use a lot less energy while still achieving the desired outcome.

Net Zero Strategy: Build Back Greener

A chance to be more green

Switching to an air blower-driven Air Knife system isn't just about saving money on energy costs. It's also about reducing the environmental impact of your production processes, cutting carbon emissions and protecting our planet for future generations. Under its Net Zero Strategy: Build Back Greener, the government is committed to supporting all UK businesses in reducing their energy consumption, but particularly the industrial and manufacturing sectors who are naturally hungry consumers of energy.

A wide range of industrial uses

As well as being energy efficient, air blower-driven Air Knife systems are highly versatile. They're used productively and cost effectively in a wide variety of industries, from automotive manufacturing and beverage production to food processing and electronics. Applications range from cleaning, cooling and drying to liquid blow-off, coating control, vacuum pressing separation, spreading and static neutralisation.