With an array of technologies and products available, finding the right industrial drying solution can be a daunting prospect. However, there's one option that stands out in terms of cost-effectiveness and energy efficiency.

Industrial drying process solutions – making the energy efficient choice

Drying is a vital component in many industrial processes, from food manufacturing to electronics. That's why choosing the right industrial drying technology and equipment is mission critical for process designers and engineers. It's not just about finding the perfect fit for your production line. It's also about making sure you get high-level performance at an affordable cost.

As well as upfront investment costs, it's just as important to take into account ongoing day-to-day operational costs. One of the key parts of the equation has always been energy efficiency.

And with electricity costs soaring, this has become even more relevant to buying decisions for all kinds of businesses, from SMEs to major multi-nationals.

There are four main types of industrial drying technologies:

Hot air drying (direct drying)

In this process, the products are put into an industrial drying oven. Air applies the heat by convection and carries away the vapour as humidity.

It also reduces air relative humidity, further increasing effectiveness and speed.

Indirect or contact drying

There are two main methods of industrial drying which fall into this category. In vacuum drying, heat is supplied by via conduction or radiation.

In drum drying a heated surface provides the energy and aspirators draw the vapour outside the room.

Dielectric drying

Dielectric heating is a term which covers both radio frequency (RF) and microwave systems.

The process can be used to support air drying or vacuum drying, reducing overall drying times, particularly at the end of the drying cycle.

Air Knives

Blower-driven industrial Air Knife systems deliver a highly-controlled, non-contact method for product drying and can easily be incorporated into any production line.

They produce powerful, laminar air flows that dry and prevent moisture contamination. Air Knives can be used efficiently in combination with a hot air drying system, removing the majority of water before the drying process is finished off in an oven or drying chamber.

How do you choose the best industrial drying system?

When choosing the right technology for industrial drying, there are two key issues to take into consideration: the level of quality it delivers and how much it can support efficient production processes and user-friendly operation.

Taking these factors into consideration, Air Knife drying systems are the go-to solution, delivering optimum cost effectiveness and efficiency for a wide range of industrial applications, including beverage production, manufacturing of automotive components and heavy industry, as well as medical, pharmaceuticals and nutraceuticals production lines.

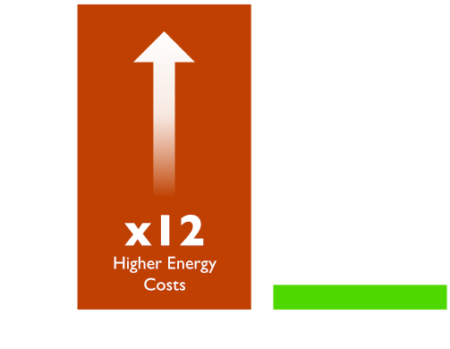

Compressed air systems use over 12 times as much energy versus a comparable air blower system.

Modern, blower-driven Air Knife systems can produce excellent results while using much lower pressure than traditional compressed air systems, potentially offering energy savings of up to 90%.

Cost-effective and versatile

Air Knife systems are cheaper to install and maintain than many other types of industrial drying systems, providing a good return on investment and a relatively low total cost of ownership.

They're also versatile, integrating seamlessly into a belt-driven production line or being easily configured to rotate around a stationary product. A range of different-sized nozzle manifolds make them adaptable to a wide variety of production processes.

At SolvAir, we're specialists in the design, installation and maintenance of high-quality, energy-efficient Industrial Air Knife systems, tailored to your needs. To find out more, call (0)1473 320307 or contact us.

Free Air Knife System - Onsite Testing

For a 100% free no-obligation consultation please contact us.

If you would like any more information on our Air Knives, or if you would like us to test an Air Knife System on your site to see if you can improve productivity and reduce costs, please contact us.

Our team of specialists will contact you within 24 hours to discuss your requirements and arrange your full in-depth consultation free of charge.