How the industrial Air Knife has revolutionised manufacturing

Providing a highly efficient method of cleaning, drying, blow-off or liquid control, the industrial Air Knife has become an essential component in manufacturing processes for all kinds of products, from automotive and aerospace parts to food and beverages.

Originally known as 'air doctors', air knives date back to the 1950s. However, the technology has evolved significantly over the years and today's state-of-the-art Air Knife systems offer exceptionally high levels of effectiveness.

However, the advantages of air knives go beyond production streamlining. Reducing energy consumption to help protect our natural resources is more important than ever for all types of businesses, but particularly for manufacturing companies, who often have high energy usage. Air Knives are extremely energy efficient, enabling businesses to achieve increased productivity while reducing their carbon footprint.

Read our full history of air knives article.

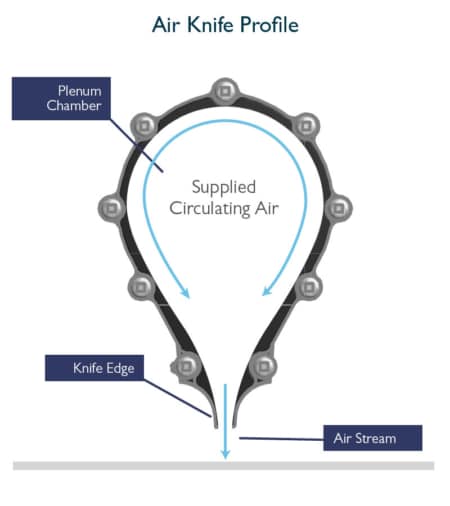

Industrial Air Knife technology - how it works

An Air Knife is a pressurised air 'plenum' or chamber with precision-engineered linear slots. When the Air Knife is attached to a centrifugal blower, air is directed at a constant high speed through these slots onto the surface of the product. The intensity of the air flow can be adjusted by reducing or increasing the width of the slots. This enables processing of a wide range of products, from foodstuffs to glass and plastics.

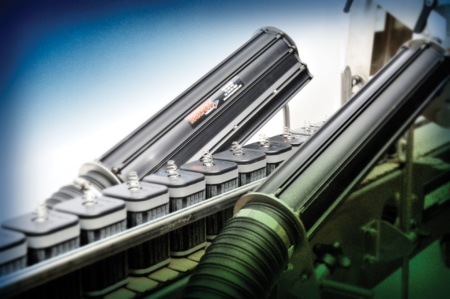

Modern blower-driven Air Knife systems can operate highly effectively while using much lower pressure than traditional compressed air systems, potentially offering energy savings of up to 90%. Systems can be set in a fixed position in the production line, with the products to be treated passing beneath them on a conveyor belt, or they can feature moveable air knives which rotate around a stationary product. Having these two options means versatility for a wide range of manufacturing applications.

Read more about how air knives work here.

Streamlined automotive production

Cost, time and energy efficiency are all mission critical to automotive production lines. That's why industrial Air Knife systems are widely used at various phases in the manufacturing process. They enable energy-efficient water removal, drying, cleaning and surface preparation for a range of components, including vehicle bodies, camshafts, engine blocks, clutch plates, trims and tyres.

Optimum drying for beverage and brewery production lines

Perfect for harsh, corrosive, wash-down or sanitary environments, Air Knife systems use ionised air to remove water and static from bottles, cans and jars. Moisture is almost totally eliminated, speeding up the labelling process and reducing the risk of corrosion. As a result, assembly and conveyor line speeds can be increased by as much as 50%.

Our Stainless Steel Air Knives are constructed with FDA Compliant 304 Stainless Steel and designed for food and beverage applications, delivering high-penetration, precision air flows efficiently, even in the toughest production environments.

Ultra-clean air for drying electrical components

Air-knife technology can remove more than 99% of moisture, dust and debris from a wide range of electrical products and components, including microchips, cells, wiring, phones, computers and TVs. Systems come in a variety of sizes and configurations, including circular air knives which deliver 360-degree air flows, making them ideal for drying cables and wires.

Air delivered by our Air Knife systems is ultra-clean (ie free of oil and moisture) and multi-stage filtration technology protects the integrity of clean room environments.

Faster food production

Incorporating an Air Knife system into the production line can significantly improve processing speeds, as well as being less costly to run than a compressed air system (see our Energy Savings page). High-powered, energy-efficient blowers deliver clean air which is free of oil and moisture, ensuring compliance with even the most rigorous hygiene standards

Precision control for pharmaceuticals and medical production

Delivering ultra-clean, ionised, moisture-free airstreams, Air Knife systems are perfect for medical devices, pharmaceuticals and nutraceuticals. Highly efficient, cost-effective and hygienic, they can remove moisture, dust and debris from surfaces, as well as eliminating static and contamination, guaranteeing the highest quality standards for processing and packaging.